Condensing Boilers

Energy Efficiency

Energy efficiency is the 'in' word at the moment. With spiralling household energy bills, comsumers are looking at all ways possible to lower their consumption of gas. And quite significantly, in 2005 there were changes to the Building Regulations, part L1, which meant you could only have a boiler installed if it was higher than 86% in efficiency. This didn't go down to well with the Gas industry, as the earlier versions of high efficiency appliances were still in their infancy, technology was not really where it should have been. Whenever new concepts come to the marketplace, inevitably there are challenges that have to be overcome. Sometimes, unfortunately, the consumers are the guinea pigs, trialling the new technology in their homes. There were stories of very poor reliability, but this has changed in recent times. There are some real top quality and very reliable boilers out there now, and boiler manufacturers have learnt from there mistakes.

The Age of The Condensing Boiler

All new boilers installed now have to be efficient condensing boilers, as per Government Legislation. Condensing is the way they use the gas, not the function they provide. We can have condensing combi boilers, condensing conventional heat only boilers, and conventional system boilers.

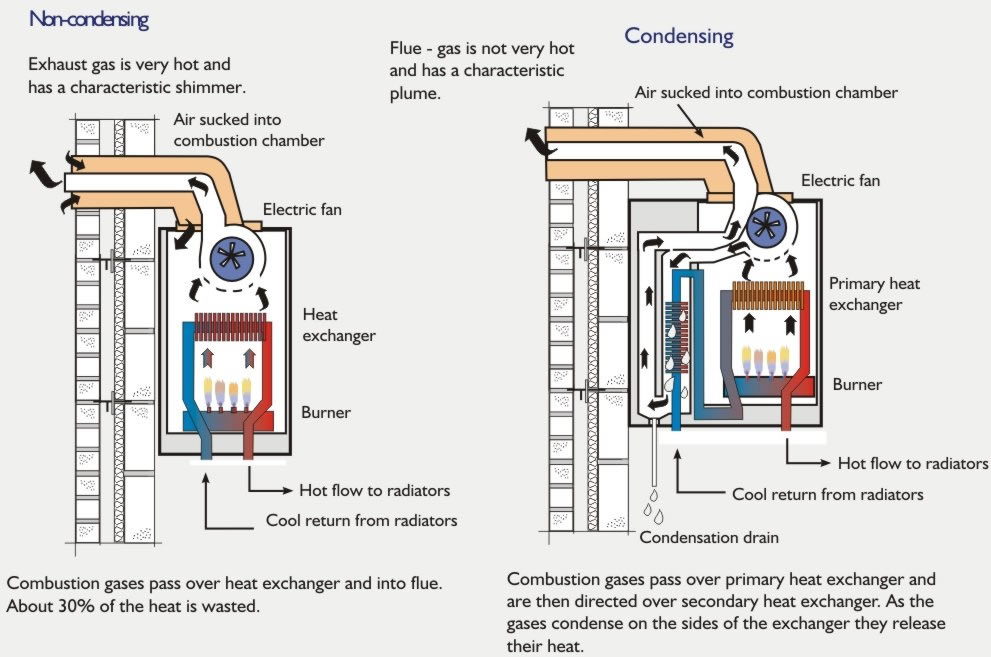

Condensing boilers use as much of the heat produced during combustion as possible, and because the flue gases come out cooler, the water vapour that is suspended in the fumes, turns back into a liquid form. Hence the name 'Condenser'. Heat exchangers inside boilers have a lot more surface area, and are much more complex than the boilers of yesteryear. Because of the water vapour turning back to a liquid, we have to get rid of this waste liquid, called condensate, into the waste drainage system. It has mildy acidic properties, so has to be run inside plastic waste pipe, and into the foul waste system, not into a rainwater soakaway.

Keeping it Simple

The easiest way to visualise how a condensing boiler works, is this;

Imagine you are heating a saucepan full of water on the gas hob, put another saucepan of water on top of this first saucepan, and you are now utilising the wasted heat from the first saucepan. You may well get some water droplets on the base of the second saucepan, as the water vapour from the fumes hits the base and cools, to form a liquid. This is the principle of condensing boilers.

Non Condensing vs Condensing Principle |

|---|

Some of the early condensing boiler manufacturers adopted this stacked heat exchanger principle, names such Malvern and the Glowworm Energysaver were two of the main ones fitted in the late 1990's.

Newer boilers nowadays use a patented stainless steel cylindrical heat exchanger, and many of the top brands such as Vaillant, Glowworm and Baxi are all utilising the design. These tend to be a lot more reliable than the old stacked heat exchanger method, as one of the drawbacks of the stacked heat exchangers was blockages in the upper heat exchanger.

To summarise, condensing is the name we apply to a boiler that re-uses the latent (wasted) heat to further heat up the water in the boiler, and as a bi-product, we get condensate liquid from the water vapour.

Things have come on a lot since the early designs, manufacturers have learnt a lot! If you are thinking of having a new boiler, don't let the myth of unreliability put you off. Choose a well respected brand and you can't go far wrong.